|

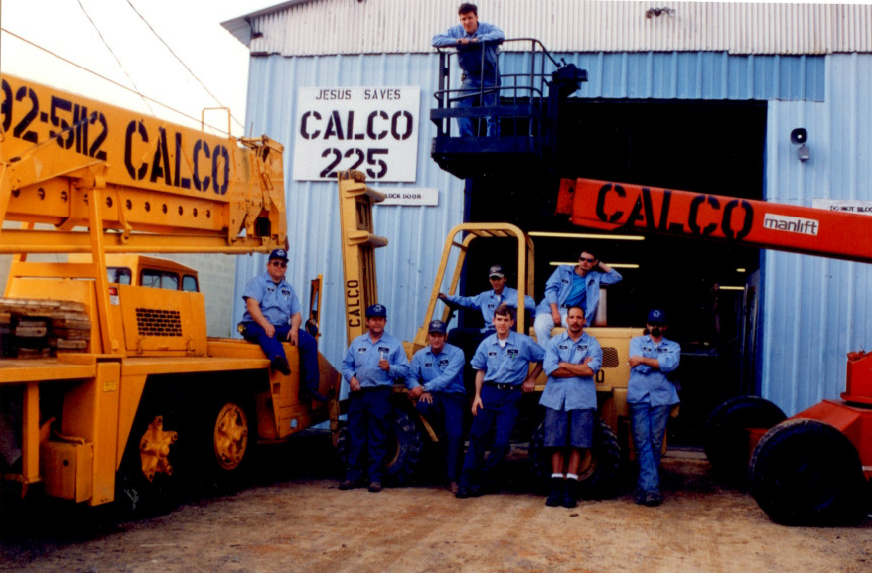

< transcript from the video above - "Company History" > by: Jon Francis Okay, so back in 1985 thereabouts, my dad started his business. He was a sheet metal worker, and he started a business on the side. He was having lots of kids -- there’s eight of us, would’ve been nine. And so he began to do work on the side building chimney caps or making guards for machinery equipment. He did it starting out in the basement of our boarding house that he managed for the church. And so we got a little - me and my brother’s got a little bit of exposure there and then he put us to work. I mean, I remember one time he was like, “This piece of inch and a quarter plate weighs 1600 lbs; let’s pick it up off the truck.” We’re out there and we’re trying. Throughout the years as that progressed, he was working with us, but he also was working another job. And my dad was an extremely hard worker -- very, very diligent -- and provided for us and was - I understand now the challenges that he faced. But as he went forward, we began to grow to the point to where he decided to go full time in his business. And so he went full time, rented a shop, and we began sweeping floors and doing little things like cutting metal out. And maybe every once in a while we’d run a drill press or things like that. And as we progressed even further, we began to learn to fabricate sheet metal, learned to weld some things. When I was about 18, I began to actually have some responsibilities running a crew. We’d go out and we’d do mechanical piping. We’d do millwright type work, you know, replacing motors or rebuilding pumps, or putting chains on conveyers, that type of thing. And I remember a distinct time when I went out and my dad sent me to do some mechanical piping. First time I really had done it, but I’d been through some training and welding and gotten my certification for pipe welding. And I got there and the guy said, “Okay, what we want to do here is run the steam line and some condensate and put in a steam trap and check valve and a wash drainer and a globe valve and water separator” or whatever else he had going on there, and I’m like, “Uh-huh.” I didn’t have any idea what those things were. And so, fortunately -- and this is another example of how the grace of God has just carried us through -- that man was so kind to me when I was humble and said, “Look, man, I know I’m supposed to know what I’m doing, but I really don’t.” And he’s like, “Well, come on, son.” He was an older man, and he pretty much taught me the trade of mechanical piping systems and steam systems, and I was real thankful for that. And I think my dad - he was also a Christian man that witnessed and shared and had a big heart and gave, and so he had a testimony. And I just thank the Lord for all throughout those years of being able to work with the brethren or work with people that got to hear a testimony. And as we came up and there again when I was about 18 I started leading a crew. And then about the time I was 22, I was managing. In 2004, I owned my first company. My dad started it for me, and I was a terrible manager. I had a lot to learn. It was like putting a kid in charge. You know, you don’t know what you don’t know. And so - but the grace of God was there and merciful and helped us, and we learned, and we grew. And then I became an owner a year later with dad and partner at Calco Enterprises Incorporated. And that partnership - with my brother and Tim Bouie and Mark Francis - so there was four of us - lasted until the end of 2013. And the beginning of 2014, I started Francis Fabricators and Directors, LLC, which is the company I have now, but I converted it to an S corporation in the beginning of ’15. So that’s a little bit of the history. My brother was a big influence on me growing up. He started work before me. We’d get out of school in high school and we’d go to work. We’d get out at noon sometimes and so we’d go up there to the shop and we would work some long hours. It wasn’t unusual for us to go in on a Friday afternoon and work 15-16 hours -- wee hours of the morning -- or in Saturday morning and then go back to work and over the weekend work 60 hours for my dad. But my brother -- going back -- my brother was a key influence in training me because he learned the trade first. And that man won’t let you slide. I remember taking a what’s a called a piece of tungsten used in what we call a tig welder -- it’s actually a GTAW (gas tungsten arc welding), and he said “Go sharpen this for me on the bench grinder." So I went over and sharpened the tungsten and came back. I thought I’d done a great job, but no, it wasn’t good enough. And I went back about four times, but it was that attention to detail and him training me to pay attention to the minutest detail that really gave me a leg up in coming in and running a business so I know that’s important. And so I’m thankful for my family history. Francis Steel, when I started that, I had one contract that I didn’t have any idea how I was going to get that done. I had no, like I said, when we closed the business I was a partner with with my dad and the other three men, we lost everything. We let the building the go back. We let all the men go. We lost all the welding machines, the cranes, the forklifts, the excavators, and the bobcats, all the equipment that we had. And we had no money. We had no income. We weren’t doing any work. And so when I came in, I didn’t know what I was going to do. And this one contractor approached me. “I want you to do this work.” And I didn’t know how I was going to do it, and I told him, “I don’t know how I’m going to do this.” But because of the history of coming out of where my dad and they said, “Listen, we know you. We want you doing our work. We will front you the money that you need. We will get you what you need. We will rent your equipment. Whatever you have to do, we will get it going for you.” And it was by that grace shown to me that I was able to actually operate in the beginning because there was no way I was going to be able to do that.

And so a little bit of that and the employees that I had that sacrifice, that said, “Hey, we know that you’re starting out. We know you have nothing. We’re going to work with you. We know that you’ll pay us when you can. We know that this thing is something worth pursuing. We want to be with you. We want to work for you, and we will help you.” And I appreciate those men -- handful of men, four or five of us -- that really worked ourselves to the bone and worked for free and just did a lot of sacrificing. And so that kind of is little baby steps that we took. And we couldn’t take on anything big, and we just took what we could. And as the time progressed, we got more and more and more and more to where over the past few years now we’re running, you know, 25-30 men or employees -- some of those are ladies -- in the company. And Francis Steel is getting a lot of opportunities and we are pursing and have just been notified that we will receive AIC Certification. And so there’s a lot of things and I see in the future endless possibilities. And I would just say it’s -- where does the Lord want to take this? ... And one guy called me, and he said, “You know, you talk a lot. But every business needs a talker.” Okay. Thank you. ... I’m John Francis with Francis Steel Incorporated, and now you know the history of my business.

4 Comments

1/26/2023 09:36:35 pm

I'm grateful that you said that you'd received pipe welding certification after undergoing some welding training. My sister wants to have her pipes welded for her. I'll advise her to choose a welder with certification.

Reply

3/9/2023 01:11:48 am

I really appreciate your work especially the research part of it which made the whole point very easy to understand. After all I’ll be subscribing on your feed and I am hoping you write again very soon.

Reply

3/24/2023 07:50:29 am

It’s interesting to read what other people thought about Steel Company and how it relates to them or their clients, as their perspective could possibly help you in the future.

Reply

5/17/2023 07:30:11 am

This post from Francis Steel's blog goes deep into the company's history, giving readers a view into Francis Steel's beginnings, development, and impact on the steel industry. Important achievements, noteworthy projects, and the company's dedication to providing high-quality steel products are highlighted in the post. It displays the company's proficiency and commitment to excellence while also providing a sense of pride and tradition.

Reply

Leave a Reply. |

Details

AuthorKeeping you posted on projects, the industry & Francis Steel. Archives

October 2021

Categories |

RSS Feed

RSS Feed